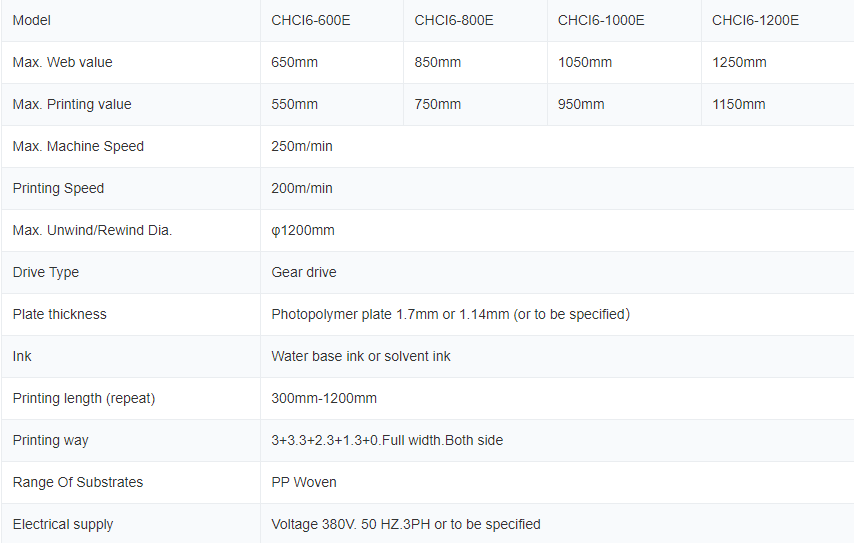

Parameter

Process Flow Diagram

Cental drum

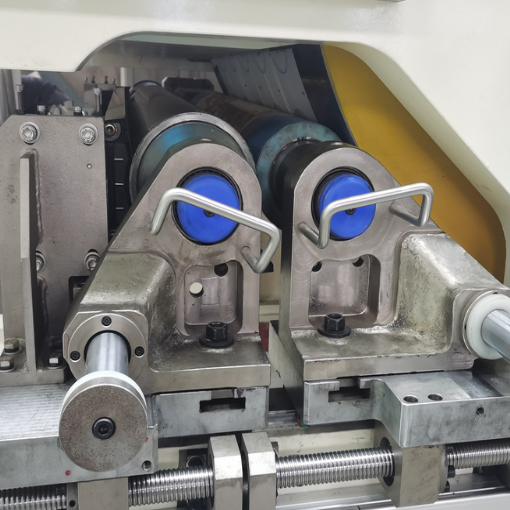

Basic structure: it is a double-layer structure steel pipe, which is processed by multi-channel heat treatment and shaping process. The surface adopts precision machining technology. The surface plating layer reaches more than 100um, and the radial circle run out tolerance range is + / -0.01mm. Dynamic balance processing accuracy reaches 10g Mix ink automatically when the machine stops to prevent ink from drying When the machine stops, the anilox roll leaves the printing roller and the printing roller leaves the central drum.But the gears are still engaged. When the machine starts again, it will reset automatically, and the plate color registration / printing pressure will not change.Electrical Parts

Power: 380V 50HZ 3PH Note: If the voltage fluctuates, u can use voltage regulator, otherwise the electrical components may be damaged. Cable size: 50 mm² Copper wire

Printing Sample

Our certificate

Packaging and delivery

Video